Environmental Monitoring of Nitrates and Other Water Quality Parameters: pH,

Environmental Monitoring of Nitrates and Other Water Quality Parameters: pH,...

Organising and planning the winemaking process is as important as the planting and picking of the fruits. Today’s winemaking process should integrate analytical testing and equipment to test pH, SO2, TA and Brix.

Hanna Instruments have put together a guide of tools and equipment used in winemaking to help you get ready for the season and get accurate and consistent testing results.

The following are the essential things you need to do for the successful testing of your wine.

Using fresh products is crucial for successful winemaking. Make sure that buffers, solutions, and reagents are within their stated shelf life. If they have been open for more than six months, they should be replaced.

Calibration buffers: Always use fresh buffer solution for calibration as this ensures that the buffer being used is not contaminated. Please keep track of how long the solution has been opened and check its expiration date. Sometimes, these solutions may expire before the specified expiration date due to evaporation and influx of atmospheric carbon dioxide.

Hanna Tip: When measuring pH in wine, it is best to calibrate to two points. Most meters will allow for pH 7.01 and pH 4.01 calibration. Ideally, calibration should be done to pH 7.01 and pH 3.00. This allows the calibration to bracket the expected value, which for wine is less than pH 4. Some meters are pre-programmed or allow for a custom calibration point (i.e. pH 3.00).

Electrodes may become dirty from regular usage and may produce inaccurate readings. A clean electrode is critical for an accurate and stable pH reading. The use of an electrode cleaning solution will eliminate any impurities and residues. Residues can accumulate on the surface of electrodes when immersed in samples during measurement or when stored incorrectly. Additionally, clogging of the junction will result in increased resistance, sluggish and erratic readings, and affect the junction potential. To ensure that the probe is clean and to prevent any clogging of the junction, consider cleaning the bulb and junction of your electrode periodically with an electrode cleaning solution.

Hanna Tip: To remove stains and deposits accumulated on the electrode’s surface, use the Hanna electrode cleaning solution for wine deposits and stains. These solutions are preferred over a general-purpose cleaning solution as they are formulated for a specific purpose.

The electrode storage solution is specifically formulated for keeping the pH bulb hydrated and maintaining a free-flowing junction. Electrodes must always be kept in storage solution when not in use. The diffusion of the internal electrolyte through the junction will be impeded if the junction is allowed to dry out. The potential of the junction, stability and response time of the electrode will be adversely affected if it is left to dry out. Therefore, electrodes should be stored correctly; otherwise, the life and performance of the electrode will rapidly deteriorate.

Hanna Tip:

As the electrolyte level inside refillable pH or ORP electrode gradually drop over time, it must be topped up with the appropriate electrolyte refill solution to maintain an adequate level. This will ensure a positive head pressure, thus allowing for the electrolyte to flow through the junction into the sample. This is crucial as the ions in the electrolyte electrically connect the meter and electrode with the wine sample being tested. Check the levels of electrodes regularly.

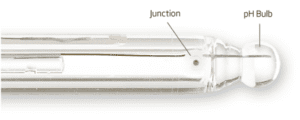

Hanna Tip: Single junction pH and ORP electrodes use potassium chloride (KCl) solution saturated with silver chloride (AgCl), while double junction electrodes use only KCl. The diagram below will help you to identify what type of electrode you have.

Electrodes should be checked for functionality before using them. The overall condition of your electrode depends on offset (pH7.01 mV value) and slope (difference between pH 7.01 mV and 4.01 mV). It is crucial to maintain them, and any deviation from the recommended values will result in erroneous readings.

The following is the procedure to determine the condition of your electrode and prepare them for your next use.

Hanna Tip:

Need a new electrode?

Hanna Instruments offer a wide range of pH and ORP electrodes suitable for various applications. For analytical measurements of wine, using an electrode that resists clogging of the junction by the solids in the sample is essential. The following pH and ORP electrodes are recommended for pH/mV meters and titration systems.

The HI10480 is a digital pH electrode with a built-in temperature sensor. This electrode is specifically designed for measuring pH in wine with a unique outer junction made of PTFE.

Here are some of the key features of the HI10480 pH electrode.

CPS Sleeve Junction

CPS™ (Clogging Prevention System) is an innovation in electrode technology. Conventional pH electrodes use ceramic junctions that clog quickly when used in wine. When the junction is clogged, the electrode does not function. CPS™ technology utilises the porousness of ground glass coupled with a PTFE sleeve to prevent clogging of the junction. The ground glass allows proper flow of liquid, while the PTFE sleeve repels dirt. As a result, pH electrodes with CPS™ stay fresh up to 20 times longer than conventional electrodes.

Double Junction Reference

A double junction electrode has an internal compartment surrounding the reference wire. Silver ions are present in the electrolyte of the internal compartment, which houses the Ag/AgCl reference wire; the electrolyte outside this compartment is silver-free. The double junction design means that virtually no silver from the electrode enters the sample. This design allows measurement in applications where silver ions in the sample are undesirable or silver precipitates on the junction are likely to form.

Refillable probe

The HI10480 is a refillable probe with a double junction. This fill solution, HI7082 3.5M KCl, does not contain any silver as with a single junction electrode. The absence of silver will prevent any silver precipitate from forming at the junction’s surface and clogging it. Clogging of the junction will result in drifty and erratic readings.

Titrations can be performed manually; however, automatic titration is the highly preferred technique. Using automatic titrators offers many benefits like improved accuracy and precision, ease of use, and automated calculations.

The following is a quick guide to prepare automatic titrators and other related equipment.

Mini Titrator for Measuring SO2 in Wine – HI84500

The HI84500 is a fast, accurate, and affordable automatic mini titrator designed for testing free or total sulphur dioxide (SO2) levels in wine. Based on the Ripper Method, this mini titrator uses an optimised, pre-programmed method of analysis with a powerful algorithm that determines the completion of the titration reaction using a specialised ORP electrode.

Download quick guide for HI84500

Mini Titrator for Measuring Titratable Acidity in Wine – HI84502

The HI84502 is a simple, fast, and affordable automatic mini titrator designed for testing total acidity levels in wine. Based on an acid-base titration method, this mini titrator uses an optimised pre-programmed method of analysis with a powerful algorithm that determines the completion of the titration reaction using a specialised wine pH electrode.

Mini Titrator for Measuring Formol Number in Wine – HI84533

The HI84533 is a simple, fast, and affordable automatic mini titrator designed for testing formol numbers in wine. Based on an acid-base titration method, this mini titrator uses an optimised pre-programmed method of analysis with a powerful algorithm that determines the completion of the titration reaction by using a glass body pH electrode.

Consider upgrading your mechanical refractometer to a digital refractometer as it is highly preferred by many due to its ease of use and improved accuracy. Additionally, a digital refractometer will require less maintenance as compared to a mechanical refractometer. The HI96811 and HI96813 are wine-specific refractometers manufactured by Hanna.

Digital Refractometer for Sugar (% Brix) Analysis in Wine – HI96811

The HI96811 is a rugged, portable digital refractometer designed for sugar measurement in wine. This refractometer reports sugar content as % Brix and has a high accuracy of ±0.2%. The operation of this refractometer is simplified by having only two buttons: one button is to calibrate using distilled or deionised water, and the other one is to measure.

Digital Refractometer for % Brix and Potential Alcohol (% V/V) Analysis in Wine – HI96813

The HI96813 is a rugged, portable digital refractometer designed for sugar (% Brix) measurement and potential alcohol measurement (% V/V) in wine. This refractometer features a high accuracy of ±0.2% Brix and 0.2% V/V potential alcohol. All readings are automatically compensated for temperature variations according to the ICUMSA Methods Book standard and displayed within a 1.5-second response time.

Both refractometers convert the refractive index of wine to % Brix. This conversion is based on the tables found in the ICUMSA Methods Book (International Commission for Uniform Methods of Sugar Analysis) that documents the changes in refractive index with temperature for a percent by weight sucrose solution. Since the majority of sugar in grape juice and in the must is fructose and glucose instead of sucrose, the reading is sometimes referred to as “Apparent Brix”.

Some of the features of HI96811 and HI96813 are listed below.

Cannot find what you are looking for or need more information about how to prepare for a successful wine testing? Get in touch with a Hanna representative right away.

Environmental Monitoring of Nitrates and Other Water Quality Parameters: pH,...

Salt Concentration In A Brine Solution For Curing Salmon Traditionally,...

To empower customers to achieve quality by supplying intuitive, accurate, and reliable analytical instruments with exceptional customer service and value.

We take pride in every product we build. From an original idea to a completed product ready for testing. We oversee every aspect of the manufacturing process. It is this level of attention to detail that sets us apart.

To empower customers to achieve quality by supplying intuitive, accurate, and reliable analytical instruments with exceptional customer service and value.

We take pride in every product we build. From an original idea, to a completed product ready for testing. We oversee every aspect of the manufacturing process. It is this level of attention to detail that sets us apart.

To empower customers to achieve quality by supplying intuitive, accurate, and reliable analytical instruments with exceptional customer service and value.

We take pride in every product we build. From an original idea, to a completed product ready for testing. We oversee every aspect of the manufacturing process. It is this level of attention to detail that sets us apart.