Environmental Monitoring of Nitrates and Other Water Quality Parameters: pH,

Environmental Monitoring of Nitrates and Other Water Quality Parameters: pH,...

A Refractometer is a scientific instruments that measures the refractive index of a substance, which can be used to determine properties such as concentration, purity, and specific gravity.

The refractive index is related to the concentration or purity of the substance, which makes it useful for many applications, such as food processing, agriculture, automotive, and more.

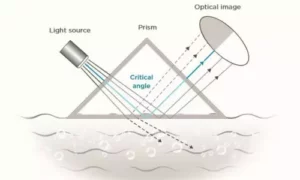

In a refractometer, a sample of the substance is placed on a prism or a lens, which refracts the light passing through it. The angle of refraction is then measured and compared to a reference scale or a digital display, which gives the refractive index in a specific unit of measurement, such as Brix, salinity, or specific gravity.

The first refractometer was invented in the late 19th century by Ernst Abbe, a German physicist and mathematician. His invention was based on the principle of total internal reflection, which occurs when light passing through a substance is completely reflected back when it encounters a boundary with another medium.

Abbe’s refractometer was initially used in the field of gemmology, where it was used to determine the refractive index of gemstones. However, it soon found applications in other fields, including pharmaceuticals, automotive, and food and beverage industries.

One of the earliest uses of refractometers was in the food and beverage industry, where they were used to measure the sugar content in liquids such as juices and wines. Refractometers were also used in the production of honey, jams, and other preserves to ensure the desired level of sweetness.

There are several types of refractometers available in the market today, each with their own unique applications and features.

Some of the commonly used types of refractometers include.

These are portable and easy-to-use devices that are commonly used in the food and beverage industry for measuring the sugar content of liquids. They are also popular among beekeepers for measuring the water content in honey. There even exists models for seawater analysis.

These are precise instruments that are commonly used in scientific and industrial applications. They are used in gemmology for identifying gemstones based on their refractive index and in the pharmaceutical industry for measuring the concentration and purity of raw intermediate and final products.

The refractive index of a substance depends on the wavelength of light used to measure it. The most common wavelength used in refractometers is the sodium D-line at 589 nm. However, some substances may have different refractive indices at different wavelengths. In such cases, the refractometer must be calibrated for the specific wavelength used.

Automatic refractometers offer several extended possibilities over traditional refractometers. They can measure the refractive index of samples with higher accuracy and repeatability.

Some automatic refractometers may also come with software features that allow for more efficient and accurate measurements. For example, some refractometers can automatically calculate the concentration of a solution based on its refractive index. This can save time and reduce the risk of human error.

Refractometers have evolved over the years and now come with advanced features. These features enable users to get accurate and reliable measurements quickly and easily.

Some of the features of refractometers include.

In the pharmaceutical industry, documentation and validation of measurement instruments such as refractometers are critical. Automatic refractometers can simplify this process by offering automated documentation and validation features. These features can help ensure compliance with regulatory requirements and improve the efficiency of quality control processes.

The pharmaceutical industry relies heavily on accurate and reliable measurements of raw materials, intermediate products, and final products. Refractometers are used in the pharma industry to measure the concentration and purity of these products. The ability of refractometers to measure the refractive index of a substance makes them an important tool in this industry.

Pharmaceutical companies must ensure that the instruments they use for measurement are accurate and reliable. Therefore, validation of refractometers is an essential part of the process. Refractometer validation involves testing the instrument to ensure that it meets the required standards and is accurate within specified limits.

Refractometers have been an essential tool in the food industry for decades. Their ability to measure the refractive index of liquids and solids accurately has made them a go-to instrument for food manufacturers and quality control laboratories. One of the critical applications of refractometers in the food industry is measuring the sugar content of beverages, such as juices, wines, beers and more.

Sugar content is a critical factor in the production of many food products, and it affects the taste, texture, and shelf life of these products. Refractometers are used to measure the concentration of sugar in a liquid by measuring its refractive index. This process is quick, accurate, and non-destructive, making it an ideal method for quality control laboratories in the food industry.

Refractometers are also used in the production of honey, jams, and other preserves to ensure the desired level of sweetness. Honey, for example, is a natural sweetener that varies in sweetness depending on its source. The refractive index of honey can be used to determine its water content, which affects its quality and shelf life. Honey with a high water content is more susceptible to spoilage, so it’s essential to measure its water content accurately.

In addition to measuring sugar content, refractometers are also used to measure the concentration of salts in food products, such as meat and cheese. The concentration of salts in meat, for example, affects its flavour and texture, and measuring it accurately is crucial to ensuring the quality of the product. Refractometers can measure the concentration of salts by measuring the refractive index of a salt solution. This information is used to determine the quality and shelf life of the product.

Apart from sugar and salt content, refractometers are also used to measure other properties of food products, such as the concentration of acids and alcohol. These measurements are critical to determining the quality, taste, and safety of food products. In the beverage industry, refractometers are used to measure the alcohol content of beer and wine during fermentation, which helps control the flavour and strength of the finished product.

Overall, refractometers are a great tool in the food industry, allowing manufacturers to measure critical properties of food products accurately. Their speed, accuracy, and non-destructive nature make them ideal for quality control laboratories and production facilities. The use of refractometers in the food industry ensures the consistency and quality of food products and contributes to the safety and satisfaction of consumers.

One of the most common applications of refractometers is in beer brewing, where they can help you measure the sugar content of the wort and the alcohol content of the beer. Here’s how to use a refractometer for beer brewing:

If you’re a brewer, you might wonder whether to use a refractometer or a hydrometer to measure the specific gravity of your beer. Both instruments can provide accurate readings, but they have different strengths and limitations. Here are some factors to consider:

Refractometers are not just for beer brewing anymore. These handy devices can be used in a variety of applications, from testing honey moisture content to measuring automotive antifreeze freeze point to monitoring aquarium salinity levels. In this post, we’ll explore how refractometers can be used beyond the brewing world and highlight some of the best models for these specific applications.

For beekeepers and honey enthusiasts, a refractometer is a valuable piece of equipment for measuring the moisture content of honey. Honey with too much moisture can ferment or spoil, so it’s essential to check its moisture level before harvesting or storing. Here’s how to use a refractometer for honey:

One of the best refractometers for measuring honey moisture content is the HI96801 Sugar in foods refractometer; sugar content Range: 0 to 85% Brix (% Brix). It also has automatic temperature compensation and a waterproof design for easy cleaning.

For mechanics and car owners, a refractometer can be used to measure the freeze point of automotive antifreeze. This is important for preventing engine damage in cold weather and ensuring the antifreeze is effective.

For aquarium hobbyists, a refractometer can be used to measure the salinity levels of saltwater aquariums. This is important for maintaining a healthy environment for fish, corals, and other marine life.

One of the best refractometers for measuring aquarium salinity levels is the Hanna Instruments HI96822 It has a range of PSU 0 to 50, ppt 0 to 150, Specific Gravity (20/20) 1.000 to 1.114, Temperature 0 to 80°C (32 to 176°F) It also has automatic temperature compensation and a compact design.

Refractometers are versatile instruments that have a wide range of applications across various industries, including the pharmaceutical and food industries. With advanced software features, automatic temperature compensation, and connectivity options, they have become increasingly popular and user-friendly. In the pharmaceutical industry, validation of refractometers is critical to ensure the accuracy and reliability of measurements. In the food industry, refractometers are used to measure sugar and salt content, which are crucial to maintaining the quality and consistency of food products. Understanding the different uses and features of refractometers can help you choose the right instrument for your specific needs.

Environmental Monitoring of Nitrates and Other Water Quality Parameters: pH,...

Salt Concentration In A Brine Solution For Curing Salmon Traditionally,...

To empower customers to achieve quality by supplying intuitive, accurate, and reliable analytical instruments with exceptional customer service and value.

We take pride in every product we build. From an original idea to a completed product ready for testing. We oversee every aspect of the manufacturing process. It is this level of attention to detail that sets us apart.

To empower customers to achieve quality by supplying intuitive, accurate, and reliable analytical instruments with exceptional customer service and value.

We take pride in every product we build. From an original idea, to a completed product ready for testing. We oversee every aspect of the manufacturing process. It is this level of attention to detail that sets us apart.

To empower customers to achieve quality by supplying intuitive, accurate, and reliable analytical instruments with exceptional customer service and value.

We take pride in every product we build. From an original idea, to a completed product ready for testing. We oversee every aspect of the manufacturing process. It is this level of attention to detail that sets us apart.