A Worldwide Leader in Electrode Manufacturing

Since the beginning of the 1990’s Hanna has been a leader in the research & development of ORP electrode technology. The HI2000 series of digital ORP probes represent the continual evolution of the technology. The HI2000 series perform all measurements within the probe and then transfer the data digitally to a process meter with a digital probe input.

The use of digital sensors allows for a process meter to be updated measuring a different parameter without changing controllers. This technology allows for a facility that has multiple control points to only have to maintain a single version of a controller.

The other advantage is that the digital transmission of measurement data is immune to electrical noise generated by motors, pumps, and humid environments. The digital signal can be transmitted over very long distances. The HI2000 series of digital probes are available with cable lengths up to 50 meters.

All Hanna industrial digital ORP electrodes are combination type, i.e. the reference half cell and the measurement half cell are assembled in the same body. All of the probes are made with a chemically resistant PVDF body and have a pt100 temperature sensor.

Each ORP electrode is provided with an internal matching pin that helps to avoid typical problems caused by grounding loop current, such as:

- progressive damage of the electrode

- fluctuating measurements

- poor process regulation

In many industrial applications there is a potential for a ground loop. This can happen when the ground of the process line is different than the ground of a controller/transmitter.

When a traditional electrode/controller system is used, the electrode reference is connected from the electrode to the instrument and current can flow through the reference half cell, causing fluctuations in reading and serious damage to the Ag/AgCl element. The potential matching pin shields the reference from external electrical fields. Shown above, the matching pin allows the measurement to stabilize and ensures effective process regulation. In order to function properly, the matching pin has to be continuously immersed in the measured solution and for this reason is placed near the electrode junction.

Installation

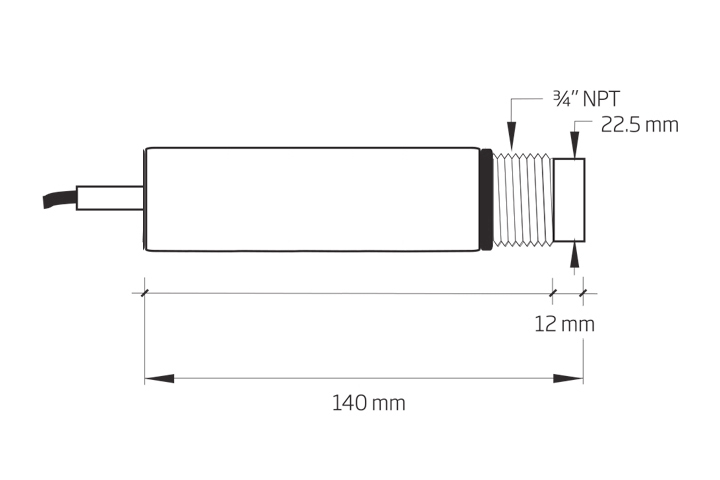

These electrodes have been designed with ¾” external thread for easy installation for in-line applications. HANNA instruments® also provides a series of probe holders for submersion tank installations.

Front thread ¾” NPT

- Direct in-line installation ¾” standard tee

- Immersion installation in vessel, tank, plating bath with HI 60501 (PVC) or HI 60503 (PVDF) electrode holders with adjustable immersion level: min 10 cm, max 70 cm

- Direct pipe installation with HI 60542 PVC electrode holder, 2″ thread

HI2000 Series Digital ORP Electrode FEATURES/BENEFITS:

Junction

Two junction types are available:

- Annular non-clogging PTFE junction, for testing solutions with high content of suspended solids, aggressive chemicals, or for high pressure installation

- Ceramic junction that is ideal for drinking water and other low conductivity applications.

Sensor Material

HI2000 series is available with two types of sensing material.

- Sensors with a platinum band. The platinum material is preferred due to the ability to fuse with a glass support. Platinum is commonly used in oxidations reactions and for baths used for disinfection.

- Sensors with a gold band. The gold material is commonly used with reduction reactions.

Temperature Sensor

- All HI2000 series of digital ORP probes have a built-in 3-wire Pt100 sensor for temperature measurements.

Connection Type

- Electrodes are wired for direct connection to the HI510 Universal Process Controller.

Cable Length

- HI2000 digital ORP probes are available with a 5, 10, 15, 25, or 50 m of cable.

PVDF Body

- The PVDF body used for the Flat Tip Series withstands high pressure and high temperature applications, and guarantees a high chemical and mechanical resistance. These characteristics make the PVDF material the most recommended for many industrial applications.

All prices are inclusive of GST and not all items are stock items, if you require an immediate solution please send an email to sales@hannainst.com.au or call us on (03) 9769 0666.

Free standard delivery: We offer free delivery within Australia on orders over $100, typically arriving within 5 to 7 days. Delivery times may vary depending on the courier service and the recipient's location. Free shipping is not available with other offers or discounts.

Same-day despatch: Place your order before 1 PM Monday to Friday for same-day despatch. Delivery times may vary depending on the courier service and the recipient's location. Subject to stock availability.

Please note that we do not offer shipping to PO Box addresses.